Decarbonization of Iron and Steel Industries/Green Ironmaking/Steelmaking

We offer knowledge based solutions and training to decarbonize the largescale iron and steel industries by intelligent approach. Service Offerings:

-

Unlocking Green Technologies for Iron & Steel: Modelling, Simulation, and Real Data Validation

- Green hydrogen integration feasibility studies

- Electric arc furnace optimization for scrap-based production

-

Slashing Carbon Emissions in Steelmaking—Comprehensive Roadmap to Net Zero

-

Unlocking Green Technologies for Iron & Steel: Modelling, Simulation, and Real Data Validation

Waste Recycling and Utilization

We offer knowledge based solutions and training in the area of recycling and utilization of mining and plant wastes in an efficient manner. Service Offerings:

- Transforming Mining Waste into Resource—Innovation in Circular Economy”

-

Maximizing Yield from Lean Ores: Magnetizing Reduction Roasting

- Custom Process Design for Plant Waste Recycling”.

Process Control in Ferro Alloy Production

We offer knowledge based solutions and training in the area of ferro alloy production. Service Offerings:

- Optimizing and Control of Submerged Arc Melting Process for Ferro Chrome Production by fundamental analysis rigorous study of the plant data and other conditions.

- Optimize process parameters (temperature, charge mix (optimal Cr/Fe ratio), Slag condition and other key operating parameters) with maximum recovery of chromium.

- Evaluate the techno-economics of the process and its economic viability and environmental sustainability.

Operational Support

We help in providing pyrometallurgical operation support, data acquisition, validation, analysis, lab-scale experiments, and simulations for optimized process control. Service Offerings:

- Induction furnace based steelmaking Process refining and quality control.

- BOF Process control and optimization

- Blast Furnace Optimization and Control

- EAF process Optimization and Control

- Quality Control in Secondary Steelmaking (RH,LF,VAD etc.)

- Process optimization and control of COREX/MIDEREX based alternative ironmaking processes.

- Process Optimization and Control of Copper Smelters and Refineries

Extractive Metallurgy for Critical Metals, Rare Earths for Battery, EV, Energy Storage applications

We will also involve in critical mineral, rare earth extraction particular to:

-

Optimizing Lithium, Cobalt, and Nickel Recovery for Battery Supply Chains

-

Engineering Rare Earth Magnet Supply—Sustainable Extraction for EVs

-

Process Flow Sheet Development for Emerging Energy Materials

Plant Process Optimization and Control

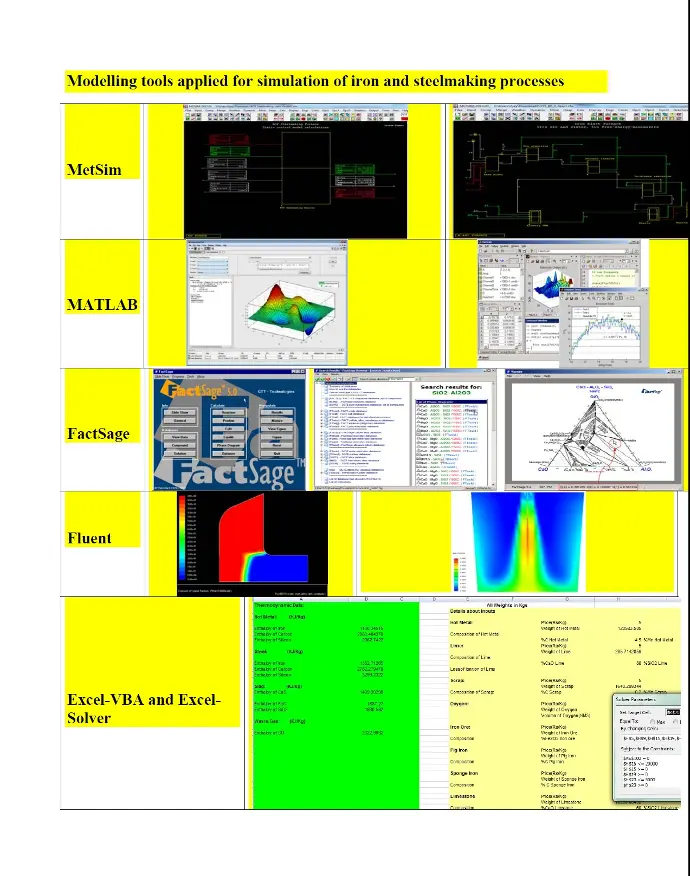

We conduct simulation studies of large scale industrial processes , validating them with industry data using industry-based data to upscale and optimize large scale industrial metal extraction processes to commercial scale, integrating techno-economic considerations, employing fundamental as well as advanced data based mathematical modeling using AI and machine learning:

- From Pilot Plant to Commercial Scale—Techno-Economic Optimization

- Data driven solution for industrial process and smelters

- First Principles Simulation for Process optimization and Scale-Up

- AI-Enabled Process control solutions

R&D Lab Setup

We offer comprehensive R&D lab setup design, equipment planning, and high-precision equipment sourcing adhering to ISO standards.

Metallurgical Testing and Mineral Characterization

We help in providing customized reports for mineral chemistry characterization and chemistry studies, assessing liberation tendencies, particle size distribution, interlocking phases, and beneficiation from low-grade to high-grade ores. We also help in providing the detailed customized reports based upon advanced characterization techniques for ferrous and non-ferrous raw materials and products, including XRD, SEM-EDS, XRF, ICP-OES, TGA-DTA, DSC, and FTIR analysis.

High-Temperature Furnace Design

We will provide support in design of high-temperature furnaces tailored for lab-scale applications.

Workshops, Training Programs and Short Courses in Potential Areas of Mining and Metallurgy like:

- Customized courses/workshop for Blast Furnace, DRI, and Steelmaking Shop Floor Operators and R&D Personals

- Courses of Inclusion Engineering and Quality Control during Secondary Steelmaking Process for Shop Floor Operators and R&D Personals

- Courses/workshop on Copper Extraction by Pyrometallurgy Route for Practicing Engineers and Scientists

- Specialized Courses to Train Academic and R&D Personals in Process Engineering Principles and Software in Pyrometallurgical Metal Extraction Area.

- Courses of Fundamentals of Various Aspects of Process Metallurgy Like Slag Chemistry and Systems, Resource Balance, Transport Phenomena and so on.

- Courses on Decarbonization Efforts and Development of Technology Road Map for Iron and Steel Sector.

- Courses/Workshop on Sustainable Extraction of Critical Minerals and Rare Earths and Development of Their Process Flow Sheets.

- Courses/Workshop on Sustainable Processing of Iron ore Minerals.

- Industry Workshops: Decarbonization Implementation for Shop Floor and Management

Metals & Mining Market Intelligence & Financial Forecasting

Combines our metallurgical process knowledge with specialized market research in key areas like:

- Commodity Price Forecasting: Short- and long-term price projections for iron ore, steel products, base and battery metals

- Supply–Demand Analysis: Global and regional market balance reports, Asset‐level capacity/utilization models, green-steel uptake forecasts

- Financial Modeling & Valuation: Company and project cash-flow models, Sensitivity and scenario analyses (price, cost, capex)

Company Directors

PhD, Process Metallurgy, IIT Kanpur, India

Professor, Department of Metallurgical and Materials Engineering, Indian Institute of Technology, IIT-Madras, Chennai Founder and Director, Extractmet Private Limited (under Incubation Cell, IIT Madras, Chennai)

Email: ajayshukla@extractmet.com

Website: https://home.iitm.ac.in/shukla/

PhD, Organic Chemistry, Sagar University, MP

Director, Extractmet Private Limited

(under Incubation Cell, IIT Madras, Chennai)

Email: shubhra.awasthi@extractmet.com